Posted: Jan 1

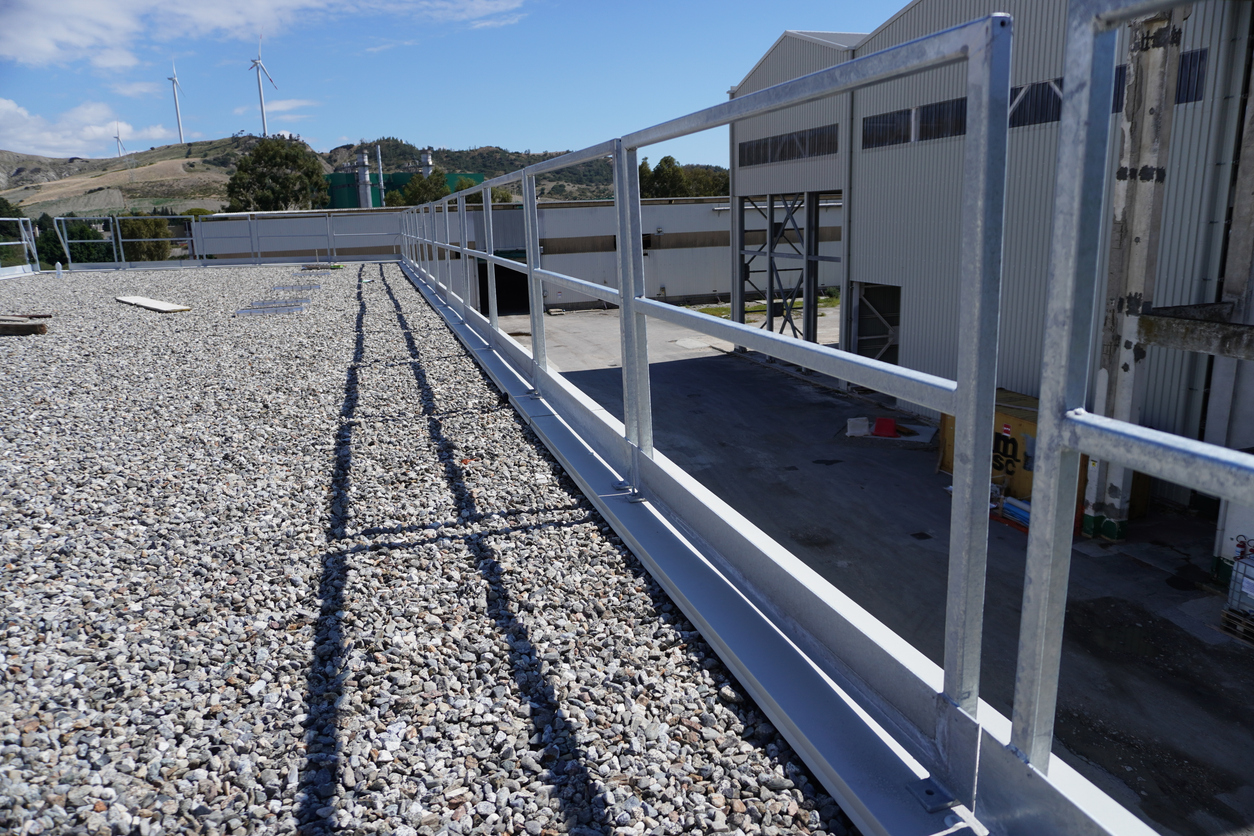

Fall protection guardrail installation is essential for ensuring worker safety in environments where falls from heights are a risk. However,

mistakes during installation and use can compromise their effectiveness. Understanding these common errors and how to avoid them can help

maintain a safe working environment. Call us today for a consultation on fall protection guardrail installation for your worksite.

Improper Spacing and Height

Fall protection guardrails need to be installed at the correct height and spacing. The top rail should be at a height of 42 inches above the walking or working surface, with a mid-rail installed halfway between the top rail and the surface. Incorrect spacing can leave gaps that increase the risk of falls.

Weak Anchoring

Guardrails must be securely anchored to the structure. Using inadequate or improperly installed anchors can result in guardrails failing when pressure is applied. Ensure that anchors are compatible with the type of surface they are attached to and that they are installed according to manufacturer specifications.

Lack of Regular Inspections

Failing to inspect your fall protection guardrail installation regularly can lead to undetected issues such as wear, corrosion, or damage. Regular inspections should be conducted to ensure that all components are in good condition and functioning correctly. This practice helps identify and address potential issues before they lead to accidents.

Insufficient Training

Workers must receive thorough training on the correct use of fall protection equipment, including how to inspect it before use and how to respond in an emergency. Onsite fire and rescue teams can play a crucial role in this training, offering their expertise to ensure that all employees are well-prepared.

Failure to Use Equipment Properly

Sometimes, workers may not use fall protection equipment correctly, either due to a lack of understanding or oversight. Ensuring that workers are consistently reminded of proper procedures and conducting regular refresher training can mitigate this issue.

Inappropriate Equipment

Using the wrong type of equipment for the job can lead to serious safety issues. For instance, using a temporary guardrail system in a permanent installation can compromise safety. Make sure to use equipment that is designed for the specific application and complies with relevant safety standards.

Misidentifying Hazards

Before fall protection guardrail installation, it's crucial to conduct a thorough hazard assessment. Understanding the specific risks in the work environment will help in choosing the appropriate type of fall protection. For example, a roof with multiple skylights may require different precautions compared to a standard flat roof.

Neglecting Personal Fall Arrest Systems

While fall protection guardrail installation provides collective protection, personal fall arrest systems (PFAS) offer individual protection and are equally important.

Incorrect Harness Fitting

A common mistake with PFAS is improper fitting of the harness. If a harness is too loose or too tight, it can cause discomfort and may not function correctly in a fall. Workers should be trained on how to adjust their harnesses for a proper fit.

Using Damaged Equipment

Regular inspections of PFAS equipment are essential to ensure there are no frayed lines, damaged connectors, or other issues. Any damaged equipment should be removed from service immediately and replaced.

Maintaining a safe work environment requires ongoing attention to fall protection guardrail installation and practices. Regular training, inspections, and updates to equipment are critical components of a comprehensive safety program.

Safety practices should be reviewed and improved regularly. Feedback from workers and onsite fire and rescue teams can provide valuable insights into potential areas for improvement. Staying up-to-date with the latest safety standards and technologies can also enhance the effectiveness of fall protection guardrail installation and other systems. For a consultation on your worksite safety, call us today!